| Mini VRF MSAN8-Y Compact design heat pump outdoor units |

Ecology and safety

R32 Refrigerant

The use of low GWP R-32 refrigerant reduces environmental impact of VRF systems, and ensures excellent performances and efficiency.

Optional safety devices are also available to reduce installation limits related to the room dimensions, increase safety and comply with regulations.

Shut-off valve

This optional device is installed next to the outdoor unit and in case of leak detection, it blocks the flow of refrigerant which is recovered and stored safely in the outdoor unit.

R-32 leakage detector

The sensor is capable of detect anomalous presence of R-32 refrigerant in the ambient and automatically start the appropriate safety measures.

Phe (plate heat excahnger) subcooling

Plate Heat Exchanger as a secondary intercooler can boosts refrigerant subcooling up to 15°C and improves heat transfer efficiency and sound.

Low standby power consuption

Thanks to the optimized conltrol scheme, the power consumption in standby mode is reduced as low as 3.5 W.

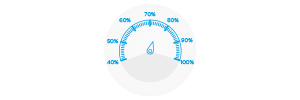

60 steps capacity limitation

In projects with limited elecricity supply, capacity can be set to output from 40 to 100% with 1% discretization steps avoiding tripping and mantaining the system in operation.

Wide application range

Wide operating range

Functioning is ensured in a wide ambient temperature range. Units can operate stabily from -15°C up to 52°C in cooling mode and from -20°C to 30°C in heating mode.

Long piping length

Total piping length is extended up to 300 m and maximum height difference between outdoor and indoor unts up to 50 m. The heigth difference between indoor units can be up to 15 m. These generous allowances facilitate an extensive array of system designs.

Enhanced comfort

Multiple priority modes

Operating mode priority can be set among 10 different modes to satisfy every specific user's need. Setting can be performed easily on field.

Multiple silent modes

Multiple modes for sound power attenuation are available depending on specific needs in the event that discrete operation of the unit is required.

High Reliability

Heavy anti corrosion treatment

Outdoor units are given anti-corrosion treatment for non-extreme conditions as standard and can also be customized with heavy anticorrosion treatment on main components for surface protection against corrosive air, acid rain and saline air (for installations in coastal regions) to extend overall useful life. The integrity of the anti-corrosion treatment is ensured by subjecting major components and parts to salt mist testing, moisture and heating testing and light aging testing.

Please contact your local dealer for further information about customization price and availability.

Refrigerant cooling pcb

Refrigerant cooling technology is used to cool the electric control box. It decreases the average temperature of electrical control components by about 8 degrees, guaranteeing the stable and safe running of the control system even at very high outdoor temperatures.

Easy Installation and Service

Fan esp up to 35 Pa

Fan motor can be set to provide an external static pressure up to 35 Pa, facilitating the installation of the unit in technical rooms or in areas where the proper airflow cannot be ensured, by installing ducts and directing the air towards the outside.

Automatic refrigerant recycling

Thanks to a specific setting, automatic refrigerant recycling allows to recover and store the refrigerant inside the outdoor unit or on indoor units side automatically when required before repairing, strongly simplifying the technical intervention.

Auto addressing

Outdoor unit can distribute addresses to indoor units automatically. Remote and wired controllers can be used to query or modify each indoor unit’s address.

Smart input / output contact

Convenient connectors are available as standard on unit PCB, to realize some convenient operations on field with other building appliances depending on users’ needs.

-Input: Two contacts available including Cooling/Heating only mode and Force stop.

-Output: One contact available including runnig status and alarm signal.

Compact and easy to transport and install

The compactness and lightness of the units allow to minimize the overall footprint, reducing the weight loaded on the surfaces and making transport easier. They can also be trasported by lifts or forklifts reducing installation time.

This makes the system particularly suitable for applications where it is necessary to limit the visual impact on the architecture, such as historic or prestigious buildings.

This website uses cookies, including third party ones, to enable website operations, for statistics, to improve your navigation experience and personalise the communications sent to you. You may accept these cookies by clinking on “Accept all” or clicking on “Preferences" to personalise your choices. On closing the banner without accepting, the website will only use technical cookies (needed for the website to operate).

For more information, even on single cookies, please read our cookie policy and our privacy circular.

United Arab Emirates

United Arab Emirates  +971 (0) 4501 5840

+971 (0) 4501 5840  info@clivet.ae

info@clivet.ae  France

France  Germany

Germany  +49 40 325957-190

+49 40 325957-190  United Kingdom

United Kingdom  India

India  Russia

Russia  South East Europe

South East Europe